by Graham Wilkes

Tail feathers sanded to shape, lots of dust when sanding wing panels and tail pieces so wear a dust mask

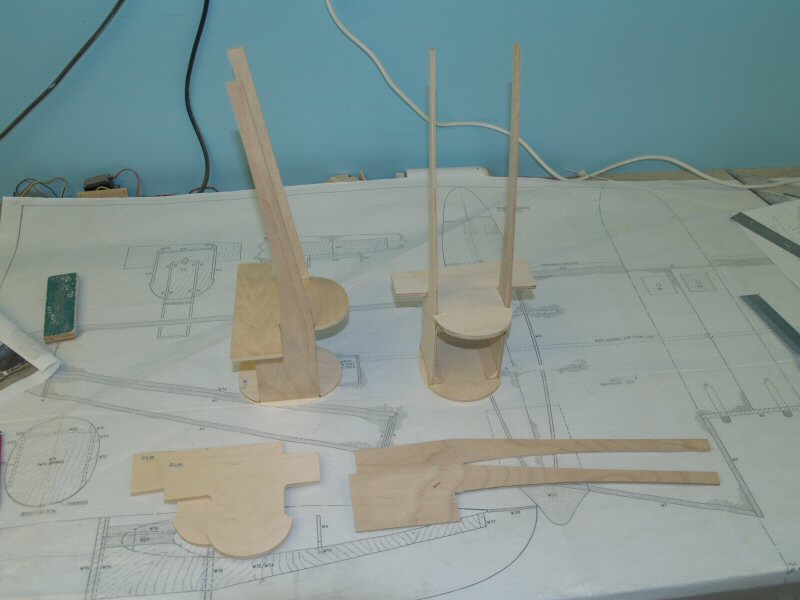

Engine nacelle frames assembled, the pieces layed in front were kit parts that were cut incorrectly and had to be replaced with new ones. The Aerotech range of kits had a terrible reputation for having parts that didn't fit or were wrong, small wonder that they ceased trading.

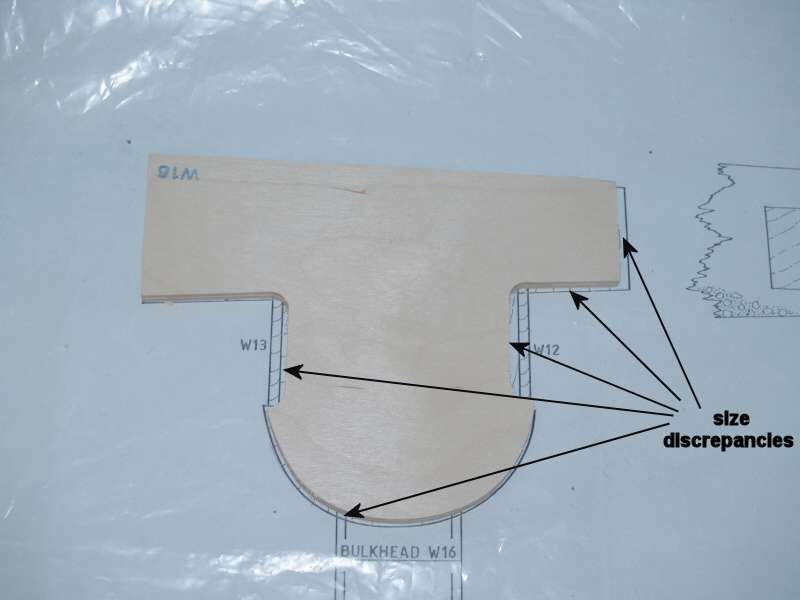

This photo shows the extent of the cut piece size discrepancy, the part is layed over the plan and as you can see is a long way from the correct size. The other part in the previous photo was about 6mm out in depth and when offered up to the wing as part of the nacelle left a large gap between it and the wing surface, this would have been impossible to attach to the wing without causing the nacelle to twist.

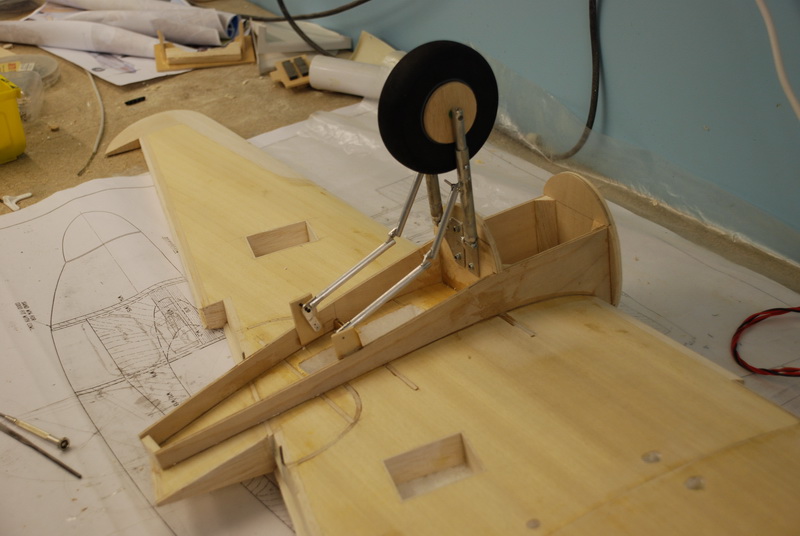

Engine nacelles fitted to the wing halves and holes for flap and aileron servos cut, the large cut out in the centre of the nacelle is a recess for the wheel to go into when retracted. Throttle and retract servos will fit into tank bay.

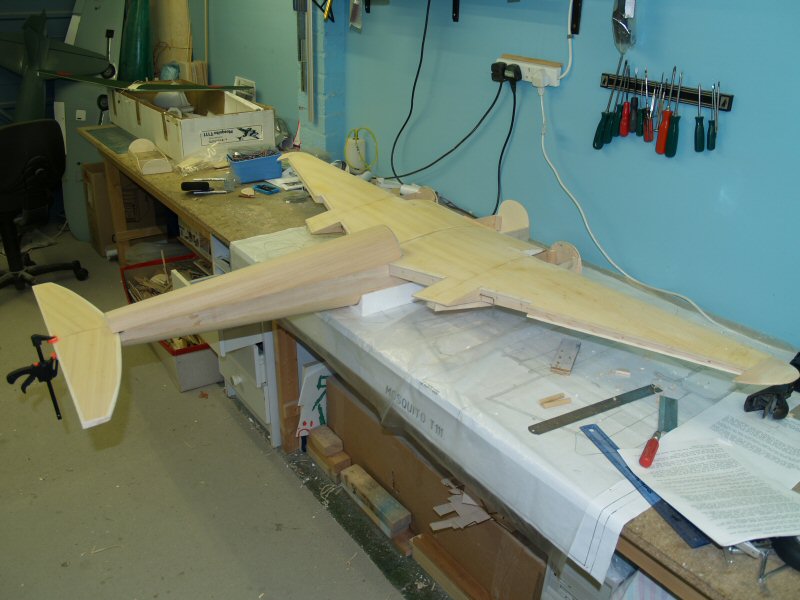

Two wing halves ready to join.

One of the two undercarriage units under construction. Each of these units will be operated by it's own retract servo.

Wing halves joined and trial fitted to the fuselage.

Tail stabilizer trial fitted to check alignment of wings..... perfect!

More detail of the undercarriage

<<Previous Page Next Page>>

|